The search results of the 「Physical testing」

Kumagai Law of Nature Machine

Industrial company > Problem > Physical testing

Physical testing / Absorption

- No.2076

- [JIS]P-8141-2004

- [TAPPI]

- [ISO]

This tester is designed to offer easy measurement of absorptiveness of liquids such as water, ink, oil and the like, and suitably used for towel paper, toilet thin paper of high absorptiveness. The specimen is suspended from the top of the pad containing liquid. After a certain span of time, the level of absorbed liquid is measured to the nearest millimeters.

Physical testing / Expantion

- No.2077

- [JIS]

- [TAPPI]

- [ISO]5635

This machine is designed to measure expansion of a paper sheet or paperboard sheet by immersing the paper in water. The specimen is fixed with the upper and lower clamps. From the upper clamp, a weight is suspended via a pulley, with the thread linked to a dial gauge. With this weight, a certain amount of tension is given to the specimen that is in the water for a certain span of time. Expansion of the specimen is indicated on the gauge.

There are two pipes on the upper lid, enabling to monitor dimensional stability of a specimen with changing relative humidity, under the circulation of the air of a constant humidity in the container.

J. TAPPI No.27-2000

There are two pipes on the upper lid, enabling to monitor dimensional stability of a specimen with changing relative humidity, under the circulation of the air of a constant humidity in the container.

J. TAPPI No.27-2000

Physical testing / Abrasion

- No.2082

- [JIS]K-6902-98

- [TAPPI]T476om-01

- [ISO]

Depending on the paper type (paper for book covers, wrapping, banknotes, etc.), paper is subject to wear and breakage due to various impacts including folding, wrinkling, friction and fluffing that may occur up to the time of its discard.

This abrader measures abrasion resistance of paper, fabric, plastic and metal material, and can test painted or plated surfaces as well as laminated or coated surfaces. This abrader incorporates a specimen stage that rotates at a fixed speed and two abrading wheels on the stage that can be rotated at a desired speed. The rotation of the specimen stage drives the wheels to rotate in the opposite directions; the rotating wheel on the right-hand side rubs the specimen from the back toward the near side while the other on the left-hand side rubs it from the front side toward the back. Those rotations create X-shaped friction trajectories crossing each other while wearing out the specimen, with each rotation leaving an arc-shaped trajectory with an external diameter of about 89mm and an internal diameter of about 63mm. The abrasion resistance of the specimen is represented by the abrasion loss after a certain number of rotations or the number of rotations that the specimen can withstand before being worn out and penetrated.

This abrader measures abrasion resistance of paper, fabric, plastic and metal material, and can test painted or plated surfaces as well as laminated or coated surfaces. This abrader incorporates a specimen stage that rotates at a fixed speed and two abrading wheels on the stage that can be rotated at a desired speed. The rotation of the specimen stage drives the wheels to rotate in the opposite directions; the rotating wheel on the right-hand side rubs the specimen from the back toward the near side while the other on the left-hand side rubs it from the front side toward the back. Those rotations create X-shaped friction trajectories crossing each other while wearing out the specimen, with each rotation leaving an arc-shaped trajectory with an external diameter of about 89mm and an internal diameter of about 63mm. The abrasion resistance of the specimen is represented by the abrasion loss after a certain number of rotations or the number of rotations that the specimen can withstand before being worn out and penetrated.

Physical testing / Internal bond

- No.2085

- [JIS]

- [TAPPI]UM-403,T569

- [ISO]

As higher operating speeds are enabled for presses and machine tools, higher quality is demanded for paper and paperboard used. Conventionally, as provided in the J.TAPPI and TAPPI UM standards, the Z-direction strength has been tested with a tensile or bursting tester that measures static strength. With that method, however, it is difficult to grasp behaviors of paper under actual operating conditions. This tester provides reliable information as a tester specialized in measurement of the following: bonding strength of coated paper, kraft paper and laminated paper, delamination resistance of paperboard, and film adhesion strength. This tester works as follows. A specimen with one-inch wide tape attached on both sides is placed on the specimen stage. An aluminum angle is fixed on the specimen. Then that specimen stage is fixed in a holder, and a hammer is struck from a horizontal position to impact on the aluminum angle. Part of the specimen should come off together with the aluminum angle. When the angle comes off, the energy loss of the hammer can be read on a scale.

Physical testing / Internal bond

- No.2085-D

- [JIS]

- [TAPPI]UM403,T569

- [ISO]

Like the No.2085, this tester dynamically measures delamination strength of paper or paperboard. It is particularly useful for obtaining pre-production knowledge on paper behaviors under severe conditions typical of a high-speed offset press. This tester automatically reads swinging angles of the pendulum to display them digitally. Push button switches provide easy operation when starting the pendulum, making zero setting of rotating friction generated by the pendulum and setting a specimen in place.

Physical testing / Sheet splitter

- No.2086

- [JIS]

- [TAPPI]UM576

- [ISO]

This tester is used in studies of sheet structures. By splitting paper into several layers, it analyzes the comprehensive formation of the cross section as well as penetrability of adhesive, ink or color. Mechanism: it uses a pair of metal rolls cooled to 0 ?C or lower, between which a sheet of wet paper or paperboard is drawn to be nipped. Then both sides of the sheet get frozen, resulting in internal tear that leads to splitting of the sheet into two frozen sheets, which are collected by a doctor shipped with the tester. Use of this tester enables preparation of more unified and larger specimens compared to conventional methods (using a microtome or a razor). Thus, it can support various research objectives involving observation of characteristics emerging in paper manufacturing such as formation, condition of wire marks, fiber length distribution across layers of paper and filler distribution as well as penetration of printing ink. If the physical characteristics of paper are likely to be affected by water penetration into the specimen, the adhesive tape method can be employed to conduct similar delamination tests.

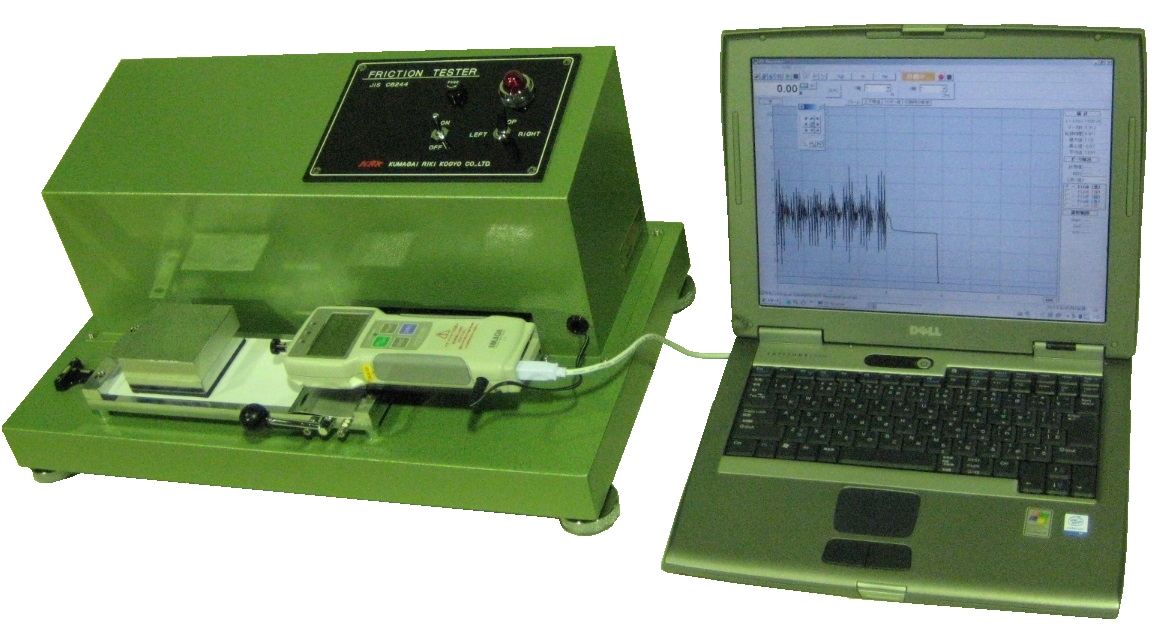

Physical testing / Friction

- No.2087

- [JIS]

- [TAPPI]

- [ISO]

The coefficient of friction on a paper surface is one measure that indicates the surface condition of the paper. This COF tester measures the coefficients of friction in the following mechanism. A 1-kg weight is placed on two overlapped sheets of the same specimen paper. While sliding the weight, coefficients of static and kinetic friction are read on a push-pull gauge.

Optionally, a recorder can be installed to help read coefficients of static and kinetic friction more easily as well as to enable recording of changes of the kinetic friction force.

Optionally, a recorder can be installed to help read coefficients of static and kinetic friction more easily as well as to enable recording of changes of the kinetic friction force.

Physical testing / Friction

- No.2088

- [JIS]P-8147-1994

- [TAPPI]T-815om-01

- [ISO]

The coefficient of friction on paper surface is one characteristic that provides a measurement for evaluating the paper surface condition. This tester helps easy measurement of the coefficient of static friction. It works as follows.

A specimen is attached onto each of the inclined driving plate and the traveling weight. As the inclined driving plate gradually increases the inclination, the weight travels at a point where the inclination exceeds the limit of the friction range of the specimen. At that point, the sensor detects the motion and stops the inclined plate immediately. The coefficient of static friction is calculated from that inclination. As the scale markings represent values of the inclination (θ) converted into tanθ, you can directly read the value of the coefficient of static friction (μ).

A specimen is attached onto each of the inclined driving plate and the traveling weight. As the inclined driving plate gradually increases the inclination, the weight travels at a point where the inclination exceeds the limit of the friction range of the specimen. At that point, the sensor detects the motion and stops the inclined plate immediately. The coefficient of static friction is calculated from that inclination. As the scale markings represent values of the inclination (θ) converted into tanθ, you can directly read the value of the coefficient of static friction (μ).

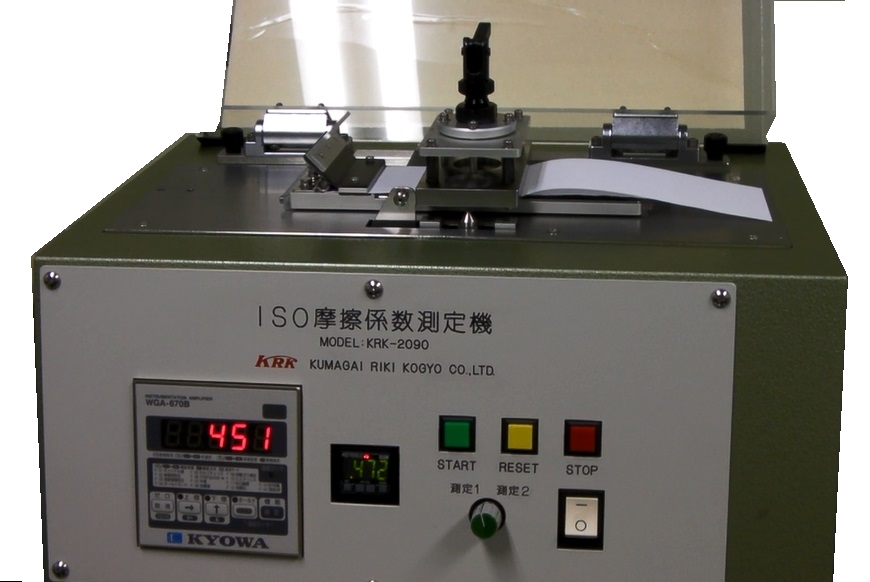

Physical testing / Friction

- No.2090

- [JIS]

- [TAPPI]

- [ISO]15359-1999

The friction coefficient of paper is one of important indices that express the paper surface condition, related to touch and ease of work of paper. This tester is based on the measurement method of friction coefficient newly specified by ISO. The friction of paper sheets applied to the moving table and weight is measured three times, to determine both static and dynamic friction coefficients. An initial torque is applied very slowly so that it takes 0.5 to 5 seconds to reach the peak of static friction. Unlike the conventional rapid measurement of static friction, this method measures friction between fibers in paper surfaces.

Physical testing / Crush

- No.2093

- [JIS]P8156-2012

- [TAPPI]

- [ISO]9895

本機はショートスパン型の圧縮試験機です。巾15mm 長さ70mmに切り抜いた試料を測定部にセットし、わずか0.7mmのスパンで試料をクランプし圧縮強度を測定します。 測定結果は圧縮荷重及び単位巾当りに換算した圧縮強さを表示します。また、圧縮状況の変化をグラフ表示します。 測定サンプルの坪量を入力しますと集計の際に圧縮係数(Compression index)N・m/gを表示します。