The search results of the 「Physical testing」

Kumagai Law of Nature Machine

Industrial company > Problem > Physical testing

Physical testing / Air permeability

- No.2060

- [JIS]P-8117-2009

- [TAPPI]T460cm-02

- [ISO] 5636-5

Paper is composed of a mesh structure with an infinite number of through-holes, concaves, and closed spaces. Air permeability test measures resistance to air that passes through the specimen. There is a relationship between air permeability and paper density, formation, water absorption and printability. Air permeability is a measure of the porosity of paper. This machine measures the air permeability of porous materials including papers, filter paper and packaging paper. The inner cylinder of a specified mass gradually moves oil downward in the outer cylinder. The time necessary for a specified volume of air to pass through the specimen is measured by stopwatch.

Physical testing / Air permeability

- No.2060-C

- [JIS]

- [TAPPI]

- [ISO]

This is an automatic counter for labor saving. It counts the signal emitted every time the slit plate mounted on the inner cylinder passes the sensor. When the count reached the preset number, the device displays the elapsed time. Use of this counter with the densometer No.2060 will remarkably increases work efficiency. By setting an air volume on the preset counter, you can make measurement with a desired air volume. A printer (optional) is also available.

Physical testing / Air permeability

- No.2061

- [JIS]

- [TAPPI]T536cm-96

- [ISO]

This machine has a configuration similar to the standard densometer, except that mercury is used instead of oil. The inner cylinder of a specified mass gradually moves downwards in the outer cylinder filled with a specified volume of mercury. The time necessary for a specified volume air pass thorough the specimen is measured. The high pressure type is suitable for impermeable materials such as coated paper, which needs 60 to 75 seconds for making 100cc air pass through the specimen on the standard densometer. Higher air pressure shortens the measurement time.

Physical testing / Air permeability

- No.2062

- [JIS]P-8117-2009

- [TAPPI]T460cm-02

- [ISO]

This machine was developed for evaluation of printability of papers according to the US TAPPI standard. It readily measures three characteristics, that is, air permeability, smoothness and flexibility. Its configuration is similar to the standard densometer. Particular attachments are used on the lower orifice plate. Under air pressure of the cylinder, air leaks across the paper layers and through the interstices of several specimens, or through the interval between special plug and specimen. The time necessary for allowing leakage of the specified volume of air is measured to evaluate the three characteristics.

TAPPI UM 574 for smoothness

TAPPI UM 574 for smoothness

Physical testing / Gloss

- No.2068

- [JIS]P-8142-2005

- [TAPPI]

- [ISO]

Gloss is one of the important factors for printing paper; the reflection at 75 degrees is wide spread for general uses, except for papers of high gloss. The principle of this machine is as follows:

Gloss amount of normal reflections is measured by irradiating light beams to the specimen at 75 degrees.

The ratio of this amount to that of normal reflection from the reference black glass surface is determined, and the obtained ratio is given as gloss degree.

This machine, according to JIS P-8142, Z-8741, is designed to measure the gloss degree of mirror surfaces at an angle of 75 degrees, with the following steps: light is irradiated to the specimen, and the light receiver receives a reflection light, converts it to electric signals and amplifies to display the gloss degree on a digital meter.

This machine is provided with an option of a vacuum specimen-fixing system to hold the specimen flat: this improves measurement precision and ease of handling. An optional printer also is provided to print out measurement data.

Gloss amount of normal reflections is measured by irradiating light beams to the specimen at 75 degrees.

The ratio of this amount to that of normal reflection from the reference black glass surface is determined, and the obtained ratio is given as gloss degree.

This machine, according to JIS P-8142, Z-8741, is designed to measure the gloss degree of mirror surfaces at an angle of 75 degrees, with the following steps: light is irradiated to the specimen, and the light receiver receives a reflection light, converts it to electric signals and amplifies to display the gloss degree on a digital meter.

This machine is provided with an option of a vacuum specimen-fixing system to hold the specimen flat: this improves measurement precision and ease of handling. An optional printer also is provided to print out measurement data.

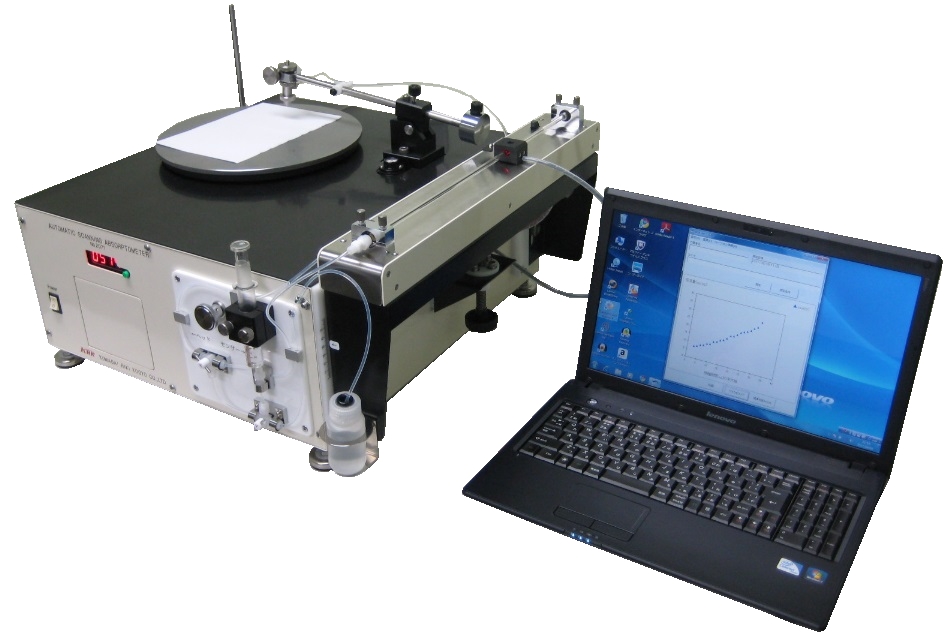

Physical testing / Absorption

- No.2071

- [JIS]

- [TAPPI]

- [ISO]

Liquid penetration behavior of paperboard is important, since it is closely related to water fastness, printability and processibility. Paper products are usually sized for improving water fastness and writing quality. The degree of sizing is an essential factor of paper quality. This absorptmeter is based on the Bristow’s method, provided with a fundamentally improved measurement system, and fully automatic measurement procedures with computer control.

Physical testing / Absorption

- No.2072-1

- [JIS]

- [TAPPI]

- [ISO]

Transfer of ink to the paper and absorption of ink by the paper through the printing process, including penetration of colors in coating, are important factors, especially when paper and paperboard are coated. Other important factors in processing papers are penetration of bond into inner cores and bonding to liners at the corrugators.

This behavior of liquid penetrating the paper layer is considerably different from that of the liquid penetrating the paper with a time span of several seconds or several tens of seconds, in the status of the paper being in static contact with liquid, as known in the conventional testing methods such as “Stockigt” and “Cobb” methods.

To grasp this behavior, the Bristow type tester is designed for the purpose of measuring absorption speed of liquid in the processes of coating, box making and printing, when the liquid is at normal pressures or pressurized.

In the status of normal pressure or pressurized, the measurement principle is as follows; the specimen is applied on the circumferential surface of a rotation disc and made to rotate at different speeds, contacting with a head box filled with a certain amount of liquid on the specimen. The specimen is rotated at a certain speed until the liquid leaking out from a slit in the head box is completely absorbed by the paper. Absorption by the specimen is evaluated with a liquid transfer area recorded.

J. TAPPI No.51-2000

This behavior of liquid penetrating the paper layer is considerably different from that of the liquid penetrating the paper with a time span of several seconds or several tens of seconds, in the status of the paper being in static contact with liquid, as known in the conventional testing methods such as “Stockigt” and “Cobb” methods.

To grasp this behavior, the Bristow type tester is designed for the purpose of measuring absorption speed of liquid in the processes of coating, box making and printing, when the liquid is at normal pressures or pressurized.

In the status of normal pressure or pressurized, the measurement principle is as follows; the specimen is applied on the circumferential surface of a rotation disc and made to rotate at different speeds, contacting with a head box filled with a certain amount of liquid on the specimen. The specimen is rotated at a certain speed until the liquid leaking out from a slit in the head box is completely absorbed by the paper. Absorption by the specimen is evaluated with a liquid transfer area recorded.

J. TAPPI No.51-2000

Physical testing / Absorption

- No.2072-2

- [JIS]

- [TAPPI]

- [ISO]

Normally, infiltration of liquid into paper is made at a certain pressure in the process of coating, printing and bonding. This machine is developed in order to reproduce the desired conditions for this test. This new type tester features a pressuring head box, instead of the normal pressure head box, to measure transfer of liquid through absorption by applying a certain pressure to the liquid.

Physical testing / Cobb size

- No.2074

- [JIS]P-8140-1998

- [TAPPI]T-441-98

- [ISO]535

The test consists in measuring absorption when a single side of paper and paperboard is in contact with water for a certain time. The tester measures the size degree of paper and board paper to determine their resistance to absorption. The specimen is placed on a metallic plate on the rubber mat. On the top of the specimen of a certain area, a metallic ring is placed and fixed. Pour water up to the level of 10mm in the ring so that the water is gradually absorbed by the specimen. The difference in weight before and after wetting (absorption amount) is read to 0.01g as absorption degree.

Physical testing / Cobb size

- No.2075

- [JIS]P-8140-1998

- [TAPPI]T-441-90

- [ISO]535

This machine is developed to test paper’s water absorptiveness by making the one side of a paper sheet or board paper sheet contact with the water for a certain span of time. This is an improved type machine that enables simplified measurement. Fixing and removing a specimen can be made with one-touch operation; you can repeat the test, using the same water-contained container.

.jpg)

.jpg)