The search results of the 「Coat/Calender/Print Coater/Dryer」

9in the case / showing1-9 case

Coat/Calender/Print / Coater/Dryer

- No.2215

- [JIS]

- [TAPPI]

- [ISO]

This coater applies coating material on the paper or paperboard with a certain thickness. With this machine, coating operation is very easy. The rubber tube is inflated uniformly with compressed air, and the blade (doctor) is pressed onto a backup roll around which the sheet receiving coating material is wound. In this status, coating is made by turning the handle. With a relief valve on the side of the machine, air pressure can be regulated appropriately reading the pressure gauge to secure the desired amount of coating material.

Coat/Calender/Print / Coater/Dryer

- No.2216

- [JIS]

- [TAPPI]

- [ISO]

This machine is an improved coater for experimental use evolved from the manual blade coater, offering better reproducibility and operability. This machine finds various uses, especially for the research of behaviors of paint at high-speed operations and formulation. The contact angle of the blade is changeable in a range of 0 to 30 degrees to allow for changes in coating thickness.

Coat/Calender/Print / Coater/Dryer

- No.2219

- [JIS]

- [TAPPI]

- [ISO]

Intensified demand for diversification and quality upgrading of printing papers requires printing modes to change more versatilely, with higher printing speed and higher printing quality. In recent years, coated papers for printing have been diversified in kinds, widely ranging from high-gloss papers to slightly coated papers. Equipped with the function of a practical roll coater, this coater offers the possibility to examine coater troubles in the laboratory by setting the various conditions that affect coating results.

Coat/Calender/Print / Coater/Dryer

- No.2220

- [JIS]

- [TAPPI]

- [ISO]

Fabrication of coated paper uses various types of coating. This size press is designed for use in the laboratory simulating the practical Sym-size press. It is composed of applicator roll, back-up roll and rod bar to make uniform color coats. The specimen, that is, sheet paper is applied on the back-up roll, and it is rotated at a high speed and made to contact the applicator roll to perform coating. Tests can be made in various conditions by changing the rod bar interval, contact pressure, rotation speed of the applicator roll, and press pressure of the back-up roll.

Coat/Calender/Print / Coater/Dryer

- No.2223

- [JIS]

- [TAPPI]

- [ISO]

In the paper making, drying is done immediately after coating. The paper coating quality is significantly influenced by the coating and drying method. With this dryer, the raw paper is applied on the moving table, and coated with color by the blade or rod, and immediately it is dried while moving in the dryer room. It enables you to determine the coating quality of the raw sheet and coloring material, and migration during drying.

Coat/Calender/Print / Coater/Dryer

- No.2225

- [JIS]

- [TAPPI]

- [ISO]

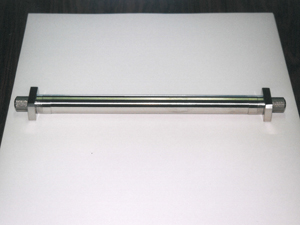

Coating rod, also called wire bar, easily applies a certain thickness of coating color over a substrate. This instrument is composed of polished stainless steel round rod wound with stainless steel wire of the specified diameter. Color that has passed valleys between wires coats the surface of paper, etc.

Coat/Calender/Print / Coater/Dryer

- No.2226-I

- [JIS]

- [TAPPI]

- [ISO]

This tool is used for making a coat of specified thickness of pigment, emulsion, etc. Put a specimen on a polished glass plate, pour a specified amount of paint over the specimen, and gently pull the bar to make a film of specified clearance thickness. A special-size bar is available on request.

Coat/Calender/Print / Coater/Dryer

- No.2226-II

- [JIS]

- [TAPPI]

- [ISO]

This bar is used for applying different thicknesses of pigment, emulsion, etc. The clearance can be adjusted as desired by thickness gauge.

Coat/Calender/Print / Coater/Dryer

- No.2227

- [JIS]

- [TAPPI]

- [ISO]

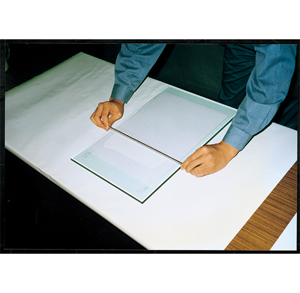

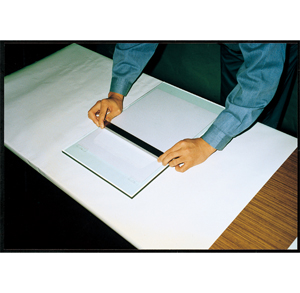

Cast coating is a method for making high-gloss (80 to 90%) paper. The processing steps are as follows: a raw paper sheet is coated with paint or ink, and the wet coat is pressed against a mirror-finished chrome-plated drum, to be dried. Procedures of test with this cast coater: a specimen is coated using a coating rod or applicator bar, and it is placed on a mirror-finished plane held at a certain temperature; then over a canvas, a rubber roll is drawn, to make the coated surface stick to the mirror-finished metal surface; after drying, the specimen is taken out.

.jpg)