The search results of the 「Coat/Calender/Print」

Kumagai Law of Nature Machine

Industrial company > Problem > Coat/Calender/Print

Coat/Calender/Print

紙質の高級化、多様化にともない、要求される品質も多岐多様にわたります。特に塗工や印刷適性、加工に対する要求も高度化しています。その一方で、製造現場においてトラブルが生じるケースも増えています。

熊谷理機工業では、印刷適正や、塗工・加工の工程におけるトラブルを未然に防ぐための試験機をご提供します。

Coat/Calender/Print / Coater/Dryer

- No.2219

- [JIS]

- [TAPPI]

- [ISO]

Intensified demand for diversification and quality upgrading of printing papers requires printing modes to change more versatilely, with higher printing speed and higher printing quality. In recent years, coated papers for printing have been diversified in kinds, widely ranging from high-gloss papers to slightly coated papers. Equipped with the function of a practical roll coater, this coater offers the possibility to examine coater troubles in the laboratory by setting the various conditions that affect coating results.

Coat/Calender/Print / Coater/Dryer

- No.2220

- [JIS]

- [TAPPI]

- [ISO]

Fabrication of coated paper uses various types of coating. This size press is designed for use in the laboratory simulating the practical Sym-size press. It is composed of applicator roll, back-up roll and rod bar to make uniform color coats. The specimen, that is, sheet paper is applied on the back-up roll, and it is rotated at a high speed and made to contact the applicator roll to perform coating. Tests can be made in various conditions by changing the rod bar interval, contact pressure, rotation speed of the applicator roll, and press pressure of the back-up roll.

Coat/Calender/Print / Coater/Dryer

- No.2223

- [JIS]

- [TAPPI]

- [ISO]

In the paper making, drying is done immediately after coating. The paper coating quality is significantly influenced by the coating and drying method. With this dryer, the raw paper is applied on the moving table, and coated with color by the blade or rod, and immediately it is dried while moving in the dryer room. It enables you to determine the coating quality of the raw sheet and coloring material, and migration during drying.

Coat/Calender/Print / Coater/Dryer

- No.2225

- [JIS]

- [TAPPI]

- [ISO]

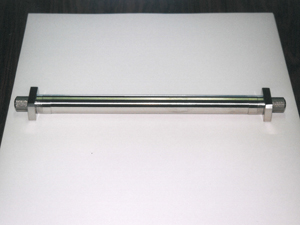

Coating rod, also called wire bar, easily applies a certain thickness of coating color over a substrate. This instrument is composed of polished stainless steel round rod wound with stainless steel wire of the specified diameter. Color that has passed valleys between wires coats the surface of paper, etc.

Coat/Calender/Print / Coater/Dryer

- No.2226-I

- [JIS]

- [TAPPI]

- [ISO]

This tool is used for making a coat of specified thickness of pigment, emulsion, etc. Put a specimen on a polished glass plate, pour a specified amount of paint over the specimen, and gently pull the bar to make a film of specified clearance thickness. A special-size bar is available on request.

Coat/Calender/Print / Coater/Dryer

- No.2226-II

- [JIS]

- [TAPPI]

- [ISO]

This bar is used for applying different thicknesses of pigment, emulsion, etc. The clearance can be adjusted as desired by thickness gauge.

Coat/Calender/Print / Coater/Dryer

- No.2227

- [JIS]

- [TAPPI]

- [ISO]

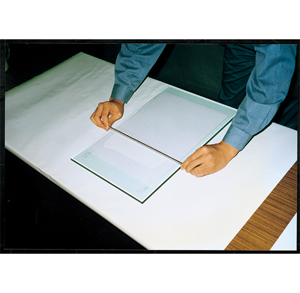

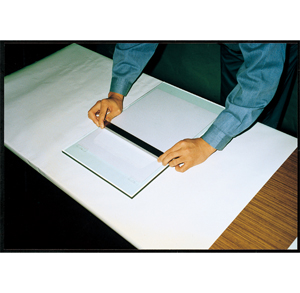

Cast coating is a method for making high-gloss (80 to 90%) paper. The processing steps are as follows: a raw paper sheet is coated with paint or ink, and the wet coat is pressed against a mirror-finished chrome-plated drum, to be dried. Procedures of test with this cast coater: a specimen is coated using a coating rod or applicator bar, and it is placed on a mirror-finished plane held at a certain temperature; then over a canvas, a rubber roll is drawn, to make the coated surface stick to the mirror-finished metal surface; after drying, the specimen is taken out.

Coat/Calender/Print / Coater

- No.2228

- [JIS]

- [TAPPI]

- [ISO]

A specimen is put on the table of this machine. An applicator is moved at a certain speed to make a layer of a certain thickness of coating material on a substrate such as paper sheet and film

Coat/Calender/Print / Calender

- No.2230_25FC-100E

- [JIS]

- [TAPPI]

- [ISO]

Calendering is performed in the finishing process of raw paper or coated paper. This process gives gloss to paper surface, improves smoothness and adjusts sheet thickness. Various mechanical constructions and roll composition are used for specific purposes. They are classified broadly into three kinds of combination: metal and metal rolls (machine calender), metal and elastic rolls (super calender), and metal and resin rolls (soft or gloss calender). It is desirable to select a test calender most suitable for the intended purpose, considering many items including material used, paper width, linear pressure, temperature, pressurizing method, heating method, sheet paper or continuous paper.

Coat/Calender/Print / Calender

- No.2230_25FF-100E

- [JIS]

- [TAPPI]

- [ISO]

Calendering is performed in the finishing process of raw paper or coated paper. This process gives gloss to paper surface, improves smoothness and adjusts sheet thickness. Various mechanical constructions and roll composition are used for specific purposes. They are classified broadly into three kinds of combination: metal and metal rolls (machine calender), metal and elastic rolls (super calender), and metal and resin rolls (soft or gloss calender). It is desirable to select a test calender most suitable for the intended purpose, considering many items including material used, paper width, linear pressure, temperature, pressurizing method, heating method, sheet paper or continuous paper.

.jpg)