The search results of the 「Pulp/Chip/Sheet former Chip classifier」

Kumagai Law of Nature Machine

Industrial company > Problem > Pulp/Chip/Sheet former > Chip classifier

4in the case / showing1-4 case

Pulp/Chip/Sheet former / Chip classifier

- No.2605

- [JIS]

- [TAPPI]

- [ISO]

In the pulp manufacturing process, it is required to have a cooking liqueur permeate to the center of the wood as quickly as possible to enable quick and unified digestion. For that purpose, this chipper is designed for laboratory use to make wood chips of unified dimensions, helping prepare various chips containing different kinds of resin. In operation, wood is pushed diagonally against the rotary disc provided with a cutting knife, which cuts off the tip of the wood. Then, produced chips are air-blown upward to the chip screens. Then, the chips are classified through two-step vibrating screens so that complying chips are sent to the chip collector rack and large-sized ones are conveyed upward on a belt to be thrown into the chipper's slot again.

Pulp/Chip/Sheet former / Chip classifier

- No.2607

- [JIS]

- [TAPPI]

- [ISO]

This dryer is used for measuring the moisture content of wood chips. Chips are placed inside the dryer for a certain length of time so that moisture content may evaporate. The moisture content is checked based on the difference between the constant mass weight of the chips and the weight before drying. In order to maintain unified temperature distribution inside the dryer, a forced circulation system is adopted for heated air, ensuring measurement of the moisture content after chips are evenly dried.

Referential standard: J.TAPPI No.2

Referential standard: J.TAPPI No.2

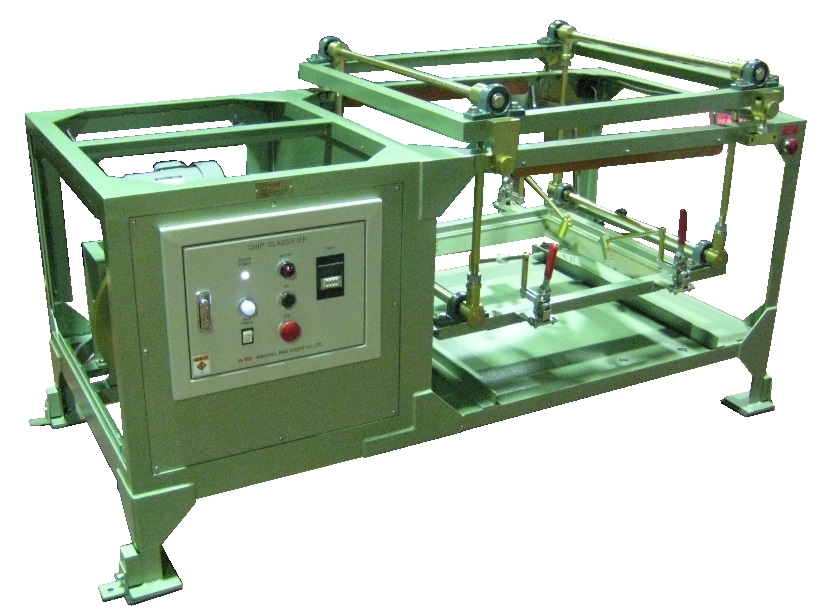

Pulp/Chip/Sheet former / Chip classifier

- No.2606-I

- [JIS]

- [TAPPI]UM21

- [ISO]

This equipment classifies wood chips into different sizes, using screens. It plays an essential production management role in making chips, ensuring production of chips of a unified size required, which contributes to securing of adequate digestion through maintenance of the chipper knife condition and efficient operation of the chip breaker and screens. It is also an important tester in commercial transactions that helps quality identification when purchasing wood chips. Screens of various types are assembled in the ascending order of the opening diameters. Chips are input into the screen with the largest opening first, and then they are vibrated to drop them through the screen to lower screens. Thus, chip specimens are classified by size to leave only small splinters collected in the bottom trash retainer at the end. You can check the distribution of chip sizes by weighing both the specimens left on the respective screens and in the trash retainer.

Referential standards: J.TAPPI No.4

Referential standards: J.TAPPI No.4

Pulp/Chip/Sheet former / Chip classifier

- No.2606-II

- [JIS]

- [TAPPI]

- [ISO]

Like the mode I, this equipment is also used for chips classification. Compact in size, this classifier provides superior operability. The screen box allows various combinations of holes with different shapes including round ones and slits. The box can also be mounted or removed easily.