The search results of the 「Physical testing」

Kumagai Law of Nature Machine

Industrial company > Problem > Physical testing

Physical testing / Tensile

- No.2000-C

- [JIS]P-8113-98, T-494om-01

- [TAPPI]

- [ISO]24-Feb

This tester holds both sides of the test specimen and pulls it at a constant speed, to determine the maximum load up to failure and the elongation at failure, and the work required for failure. When a specimen is inserted into this constant-rate-elongation machine, it is secured by two pneumatic clamps, then the test starts automatically. The load cell connected to the fixed side clamp detects load, to calculate, display and outputs on the printer the tensile strength, elongation, breaking length, tensile energy and tensile stiffness.

Physical testing / Tensile

- No.2000-CW

- [JIS]

- [TAPPI]

- [ISO]

A specially designed wetting water supply device is mounted on the standard horizontal tensile tester. Dropping water from a dispenser, you can easily measure the wet tensile strength with this machine. Immediately after water in the dispenser is dropped on the specimen, the tensile test is performed. The amount of wetting water and the timing of test start after water dropping can be set as desired.

Physical testing / Tensile

- No.2001

- [JIS]

- [TAPPI]

- [ISO]

A constant-speed loading type tensile tester. This machine applies a tensile load onto the specimen at a constant speed, to measure the maximum load and elongation at breaking.

One end of the specimen is fixed with the clamp connected to the pendulum, and the other end is secured by the clamp that moves downward at a constant speed.

The test specimen is tensioned at a constant speed, while the load increases. When the specimen breaks, the pendulum stops, and the machine indicates the maximum load and elongation at breaking. The tensile strength is expressed in Newtons, and the elongation in millimeters or ratio (percentage) to the specimen length (180mm). Since the machine is provided with a stepless speed change motor, the tension speed can be changed as desired. The lower clamp is lowered and lifted by the push button. So you can easily perform tension, stop and resetting. When the lower clamp reaches the lowest point, the machine stops automatically to ensure safety.

J.TAPPI No.18

One end of the specimen is fixed with the clamp connected to the pendulum, and the other end is secured by the clamp that moves downward at a constant speed.

The test specimen is tensioned at a constant speed, while the load increases. When the specimen breaks, the pendulum stops, and the machine indicates the maximum load and elongation at breaking. The tensile strength is expressed in Newtons, and the elongation in millimeters or ratio (percentage) to the specimen length (180mm). Since the machine is provided with a stepless speed change motor, the tension speed can be changed as desired. The lower clamp is lowered and lifted by the push button. So you can easily perform tension, stop and resetting. When the lower clamp reaches the lowest point, the machine stops automatically to ensure safety.

J.TAPPI No.18

Physical testing / Peeling

- No.2004-I

- [JIS]

- [TAPPI]UM584

- [ISO]

Optional jigs used with the tensile tester for measuring the internal bonding resistance of paper and paperboard. The specimen with double adhesive tape is sandwiched between two 25mm-square blocks of well-polished stainless steel, and a pressure of 150kgf is applied to stick the specimen to the blocks. As in the tensile test, the lower clamp is moved downward to apply a delamination load to the paper layers. Then the blocks are fixed in the clamps of the tensile tester. Tension is applied as in the tensile test to delaminate the specimen. The load at the rupture of paper layers is recorded. In addition, the position of delaminated layers is determined and the state of delaminated surface is observed.

Physical testing / Peeling

- No.2004-II

- [JIS]

- [TAPPI]

- [ISO]

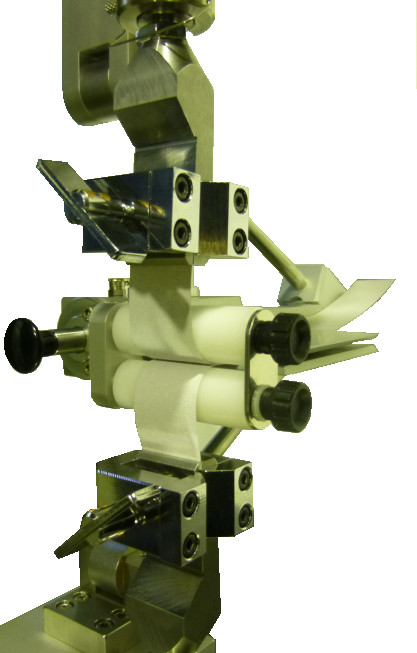

The bonding strength of adhesive paper and adhesive paper tape is usually measure by the 180° constant-speed peeling test. These jigs are mounted on the upper frame and moving crosshead of the constant-speed tensioning universal tester. The specimen is secured by the upper and lower clamps, through two low friction guide rolls, and loaded as in the ordinary tensile test. A special mechanism is provided so that the peeling point is always located in the vertical line passing the upper and lower clamps, to achieve high accuracy and reproducibility. By changing the position of the rolls, you can use this instrument for a wide range of thickness and hardness of specimens.

Physical testing / Friction

- No.2004-III

- [JIS]P-8147-87

- [TAPPI]T549om-01,T816om-92

- [ISO]

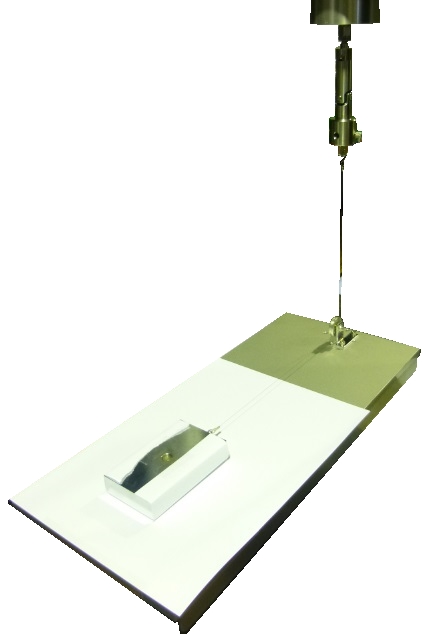

This instrument determines the friction coefficient of the surface of paper and paperboard (including converted paper), using the constant-speed tensioning tensile tester by the horizontal method. Both static and dynamic friction coefficients can be measured.

A specimen is fixed onto the wide smooth metal plate with a tape. Another specimen is applied onto the weight. A low friction pulley is positioned just below the load cell. A thread fixed to the upper chuck is connected, via the pulley, to the weight on the specimen table. As in the ordinary tensile test, the crosshead is lowered to make the weight gradually slide on the specimen. The friction in sliding is detected by the load cell and recorded on the graph. The peak friction at the moment the weight starts to move is static friction, and friction during movement of the weight is dynamic friction.

A specimen is fixed onto the wide smooth metal plate with a tape. Another specimen is applied onto the weight. A low friction pulley is positioned just below the load cell. A thread fixed to the upper chuck is connected, via the pulley, to the weight on the specimen table. As in the ordinary tensile test, the crosshead is lowered to make the weight gradually slide on the specimen. The friction in sliding is detected by the load cell and recorded on the graph. The peak friction at the moment the weight starts to move is static friction, and friction during movement of the weight is dynamic friction.

Physical testing / Tensile

- No.2010

- [JIS]

- [TAPPI]40(1) 1957

- [ISO]

This machine determines rupture stress by rapid tensioning. An impact is given to the specimen slackened to measure the energy loss at rupture. This test determines resistance of continuous paper against break on a rotary printing machine where a large tension may occur instantaneously. It also measures the dynamic strength of bags made of kraft paper in use. This tester is provided with a pendulum to measure the work of rupture of specimens. A test piece 15mm wide and 180mm long is held with the gripper, and the pendulum is lifted to the specified position and released. The specimen is broken at a maximum tension, and the work in N?m (kgf?cm) is shown on the scale.

Physical testing / Folding

- No.2015-C

- [JIS]P-8115-2001

- [TAPPI]T511om-02

- [ISO]5626

This machine counts the number of folds, which a specimen will withstand before break. The upper end of specimen is secured with the loading spring clamp and the other end with the folding clamp. The loading clamp applies a constant tension on the specimen. In this state, the folding clamp reciprocates to repeatedly fold the specimen till it breaks. The number of reciprocating actions counted is shown.

Physical testing / Folding

- No.2015-UL

- [JIS]

- [TAPPI]

- [ISO]

Acid paper, which has been used widely for about 200 years, tends to become brittle during storage. Not only books in public libraries but also private libraries may suffer from such damage. Currently, neutral paper is manufactured, replacing acid paper. However, at present, there is no tester satisfactory for evaluating deterioration of paper. With the conventional MIT folding tester, tension is too high and wear of the shaft is another problem, making it difficult to assess differences between deteriorated paper specimens. For providing a solution for this problem, we KRK developed a folding tester under an ultra-light loading range, under the direction of Dr. Oe, former professor of Tokyo University of Agriculture and Technology. The basic configuration is the same as that of the conventional MIT folding endurance tester. With this instrument, tension is given by a dead load. It has such a mechanism that shaft friction is completely removed to improve the measurement accuracy.

Physical testing / Folding

- No.2016

- [JIS]P-8114-2003

- [TAPPI]T423om-98

- [ISO]5626

This is a tester for resistance to folding of a sheet of paper or film. The specimen is inserted into a slit in the reciprocal movement metallic plate where the specimen is held at the right and left ends to be given light tension. The holding line of the specimen is subject to repeated reciprocal movement, and leads to fracture.

The number of reciprocations to cause fracture is displayed as Schopper folding resistance.

The number of reciprocations to cause fracture is displayed as Schopper folding resistance.